Choosing an outdoor system can often become a long drawn out process, with numerous risk factors to consider it becomes difficult to find a cost efficient solution with enough adequate protection. However, trying to determine the right level of security is difficult to judge, and the biggest variable, such as weather, constantly changes and produces challenges for those who choose to use outdoor screens.

Often catching us off guard, extreme weather offers little time to react properly, and as climate conditions can frequently take a turn for the worse, temperatures and situations often get dangerous fast! Recent events like North America heat waves, and record rain levels in the UK, go to demonstrate how unpredictable and dangerous weather conditions can be.

During the winter months, extreme conditions such as flash snows, frost, freezing rain and blizzards, create huge problems for advertisers, as the risk of damage and potential costs to replace digital signage equipment can be immense. While LCD’s are susceptible to condensation, pixel damage, ice scratching and falling below their operating levels, it highlights that most electronic equipment just isn’t designed for exterior elements, and will not last in any long-term outdoor plan.

However, ready to protect against such elements, an Armagard LCD enclosure is designed for a variety of environments, protecting against extreme temperatures, water ingress, dust and physical impacts. In addition, enclosures are sealed to international IP/NEMA standards, while allowing customer to install their own media player and display, and available in sizes 19” to 70”.

However, such cold temperatures are hard to simulate (without moving to the Antarctic!), and without a testing facility, trying to measure and accurately prove the validity of an enclosures protection efficiency is a very difficult process.

Temperature Testing

Offering controlled temperature testing for sustained periods of time, while providing valuable statistical findings for both hot and cold environments, the testing chamber has become essential to research and development, and allows Armagard to ensure consistent product efficiency.

Featuring an 80mm thick polyurethane wall insulation, galvanized steel floor finish and chilled by its onboard freezer unit, Armagard’s on-site environmental chamber simulates temperature testing from -40°C to 100°C. Putting theses temperature in to perspective, when the average temperature of the Arctic winter is -34.44°C, and the Sahara Desert is 30°C, the ability to test enclosures in such extreme conditions presents an excellent opportunity for product testing and industry research.

Why Testing is Important to You

In the long-run, testing procedures pass on a cost saving to you, the customer, offering a faster way to make a return-on-investment with a tested and functional product that retains a longer life-span. Damage caused from other, inferior security designs, not only cost you in terms or repairs, downtime and buying new hardware, but also the damage to your brand image as a provider of reliable advertising, or negative impressions from a blank idle screen.

Testing

Throughout this article we’ve been focusing on the importance of maintaining heat in freezing conditions, furthermore, using the testing chamber we know how an enclosure can effectively manage heat within a freezing environment, and maintain an optimal temperature for functional electronic hardware.

Testing Parameters

The test conducted involves placing an enclosure within the environmental chamber for 161 minutes, this time begins after a 35 minutes cool down period as the temperature drops to -18.25°C. To monitor the temperature within the cabinet, measuring equipment is attached inside the enclosures interior in 6 different places, each collecting a reading every minute throughout the tests runtime.

The Test Unit

Enclosure includes: Air Curtain, Heaters, Insulation, Fan Support, Automatic Thermostats, Plenum chambers

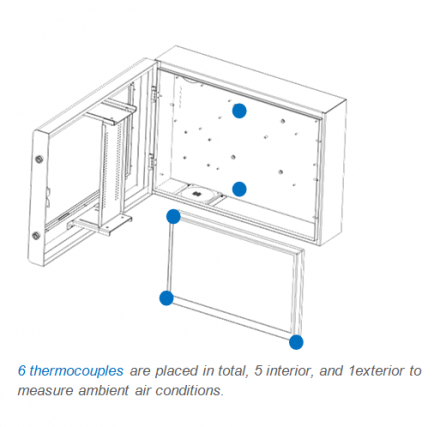

For the test we used a cold climate PDS-24” (hardware and images shown above), attached to a floor-stand and placed inside the chamber for a prolonged period of time. The equipment used inside the enclosure was a standard 22” desktop monitor with an attached media player, which supplied video and images through an HDMI cable.

During this time the ambient air temperature of the testing chambers is lowered while simultaneously the enclosure is turned on, our apparatus can then identify the variable difference in temperature readings between each area, and determine level of insulation efficiency in the enclosure.

Measuring

Capable of recording accurate temperatures from -270°C to 1370°C, and perfect for the requirements of this test, thermocouples are placed in different places around the enclosure to measure temperature variations. Collecting the data on a nearby PC, an attached data logger records the temperature every 60 seconds for over 2 hours and 43 minutes, yielding a massive 990 readings in total.

Results

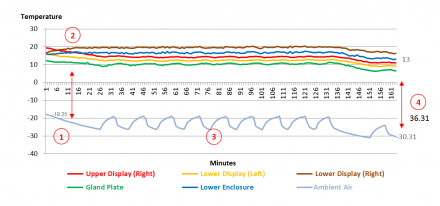

Shown above, the 6 lines representing the thermocouples show the average temperature readings over the entire test period (2 hour and 24 minutes). At a glance, the initial findings clearly show that the environmental control works as a significant difference exists between the ambient and inner enclosure temperature (1+2).

Even when the ambient air temperature alternates between -25°C to -20°C over a recurring ten minute period (3), the remaining five inner thermocouples remain consistently steady in their average heat readings.

In the lowest temperature phase of -30.31°C (4), the difference between that and the next thermocouple measurement 36.77°C, which demonstrates the significant heat insulation achieved by the enclosure.

Conclusion

The enclosure efficiently held an interior air temperature above freezing, making the test a great success. However, in practical use for a customer, Armagard’s insulation model more than adequately provides security for electronic hardware during winter months, and if an extreme event does occur, you know you’ll be covered.

Offering significant and valuable statistical analysis for an enclosures ROI (return on investment) potential, the testing chamber demonstrates how Armagard’s environmental control can maintain displays even in the harshest of conditions.