Choosing The Best Food Manufacturing Digital Display For Your Plant

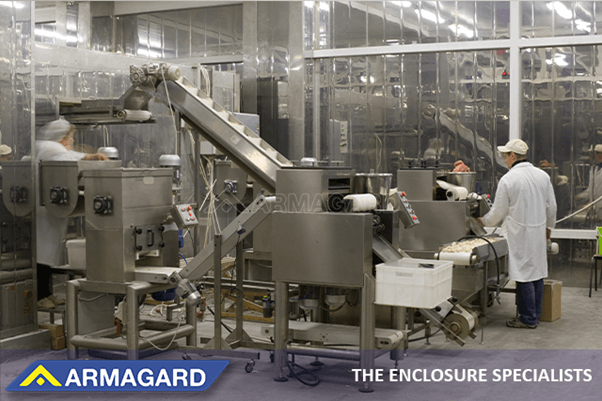

A food manufacturing digital display can improve shop-floor productivity and communication. The right solution allows you to install a TV in any washdown environment. Learn how to choose a waterproof screen solution that delivers maximum reliability, longevity, and sanitation in your plant.

Food Manufacturing Digital Displays: Enclosures Vs. Waterproof Screens

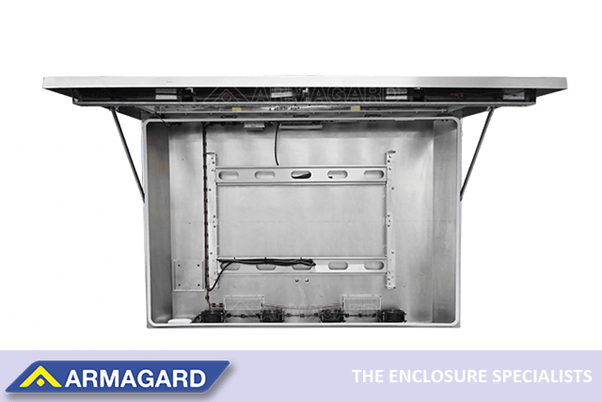

You have two options when choosing a food processing TV. The first is a purpose-built, all-in-one unit that integrates a screen into a sealed, waterproof body. The second is an enclosure-screen combination, which keeps the protective housing and screen separate.

Here are four reasons why you’re better off with an enclosure:

1. Save Money By Using The Screen Of Your Choice

A food processing TV enclosure allows you to install virtually any VESA-compatible screen of a given size. The enclosure provides complete washdown protection, so you can save money by using an ordinary TV on your shop floor.

Enclosures give you the flexibility to use a screen with the brightness rating, connectivity and other features you want. This is in contrast to purpose-built waterproof TVs, which limit your choices to whatever screen has been built into the protective body.

2. Maximize Uptime Thanks To Easy Maintenance

An enclosure provides easy and immediate access to the screen. This eliminates the need for a specialist engineer. You can quickly install, remove, and replace the display and content management system whenever you want, which maximizes uptime and reduces your reliance on third parties.

3. Benefit From A Lower Total Cost of Ownership

A food manufacturing TV cabinet has an expected 10-year lifespan. You can use the same enclosure to protect multiple screens over several years, making it a great long-term investment.

An enclosure’s longevity can make it significantly more cost-effective than a waterproof TV, which will need to be replaced entirely if it breaks beyond repair.

4. Be Reassured By Greater Impact Protection And Security

A TV enclosure gives you peace of mind about the security of your screen in production environments. Key-operated locks prevent unauthorized access, and the steel body protects against physical impact.

When compared with waterproof TVs, which might only protect against liquid, an enclosure-screen combination offers greater reassurance about the security of your investment.

What To Look For In A Food Manufacturing Digital Display Enclosure

The right TV enclosure for your plant will reflect your concerns as a food processor: sanitation, washdown protection, 24/7 reliability, and maximum productivity.

Here’s how to find an enclosure that ticks all of these boxes:

Choose 316 Stainless Steel

Boost shop-floor sanitation by choosing waterproof TV enclosures made from 316 stainless steel. This food-grade material is antibacterial, corrosion resistant, and easy to clean, so it’s ideal for sanitary industries.

Avoid enclosures made from lower grades of steel. These are more likely to harbor bacteria and could rust under washdown. Plastic is also a bad choice. Plastic enclosures can’t offer the same heating and cooling options as steel units, and they can’t withstand high-temperature cleaning.

316 enclosures, on the other hand, provide years of safe, clean, and reliable use, which makes them far more cost-effective.

Look For NEMA Or IP Washdown Protection

Choose an enclosure that guarantees washdown protection according to NEMA or IP standards. Avoid any manufacturer that uses vague terms, like waterproof or watertight, without any certification to back them up.

NEMA and IP ratings guarantee a product’s ability to withstand certain environmental conditions. NEMA 4/4X enclosures protect against most washdown procedures, and they’ve been popular in food processing for years. More recently, the IP69K standard has been introduced. This standard protects a screen from high-pressure, high-temperature jets and steam cleaning.

Either could be right for your production line. Both give you peace of mind that your food manufacturing digital display will operate reliably in wet conditions.

Ensure Adequate Temperature Protection

Check the enclosure provides the right level of temperature protection for the display. This is especially important if you’re installing a digital screen in a refrigerated environment.

For maximum screen longevity, choose an LCD/LED display cabinet with automatic climate controls. These enclosures use a controller board to automatically manage internal heating and cooling functions. The screen operates in safe, efficient conditions when external temperatures range from -22°F to 95°F, depending on the model you choose.

Favor Polycarbonate Over Glass

Choose a food manufacturing TV protector that uses shatterproof polycarbonate for the viewing window. This material is 20 times stronger than glass, and it won’t shard into tiny pieces if it breaks. In the unlikely event of a breakage, a polycarbonate screen won’t contaminate your production line, which will save you from extended downtime.

Choose An Enclosure With The Right Mounting Options

For the greatest improvements in shop-floor communication, choose an enclosure that can be mounted exactly where you want.

The best production-floor TV enclosures have ceiling, stand, or wall mounting, using flat or tilted wall brackets. This allows you to position a digital message board or KPI screen in the ideal location on your shop floor. Versatile mounting also allows you to move the enclosure into a new location in the future, ensuring it's always in the best location.

Look For A Proven Manufacturer

You expect maximum reliability, longevity, and cost-effectiveness from your food manufacturing digital displays, so find a manufacturer that provides the reassurances you want.

Armagard has a proven history of protecting screens in harsh environments. Previous customers include some the biggest food brands in the United States:

- Cargill

- Walmart

- Tyson Foods

- Smithfield Foods

- Smucker’s

- Hormel

Over 100,000 Armagard enclosures protect screens and IT equipment in 53 countries. The company has a worldwide reputation you can trust, and you benefit from industry-leading warranties and lifetime technical support.

Choosing A Food Manufacturing Digital Display: Conclusion

The right food processing TV can boost productivity, improve communication, assist sanitation, and protect uptime.

To get these benefits in your plant, choose an enclosure specifically designed to protect a screen in washdown locations. That means food-grade stainless steel, industry-rated ingress protection, temperature controls, a specialist manufacturer, and more.

Contact Armagard to discuss the best food manufacturing TV enclosure for your shop floor. Call +1-866-434-0807 for a no obligation chat, or fill in a contact form to request more information.

This post was written by Ben Telford

As Armagard’s head of content, Ben oversees the production of articles, web copy, guest blogs and more. He aims to make Armagard’s expertise in digital screen protection accessible to customers so they can choose the right solutions for them.

Find Ben on LinkedIn.